Key process steps process steps for Cell Manufacturing

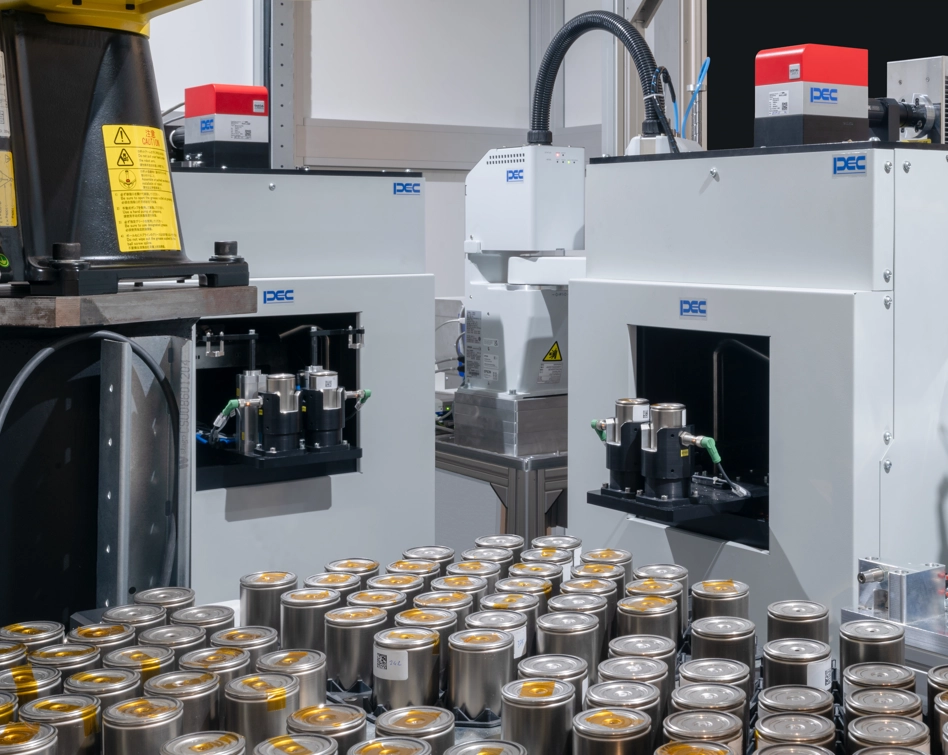

Single-Step Electrolyte filling

Electrolyte filling presents one of the key challenges in GIGA-scale, hardcase Li-ION cell production. As cell energy densities rise, achieving full electrode wetting becomes increasingly time-consuming and complex. In response, PEC has developed a unique, patent-pending Rapid Single-step Electrolyte Filling solution.

PEC’s Unique Offering:

Efficiency: PEC’s solution reduces electrolyte filling time from hours to minutes, eliminating multiple filling steps and achieving a higher state of wetting without cell modifications.

Cost Savings: The technology impacts both CAPEX and OPEX for cell manufacturers and improves yield.

Enhanced Performance: Higher wetting state of cells before formation improves overall cell performance.

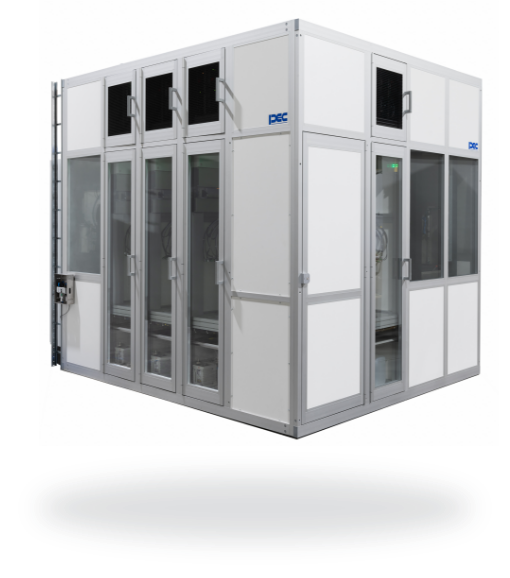

Formation and Grading Towers

The core component of our system is the formation tower, essential for the electrical activation and testing of cells post-electrolyte filling. These towers perform charging and discharging cycles to develop a uniform SEI layer within the cells and assess key characteristics such as cell capacity, internal resistance, and peak performance.

Key Features

Fully Integrated Systems: Formation towers come as fully integrated units, incorporating charge/discharge electronics, measurement instrumentation, controls, and formation chambers. Installation is streamlined, requiring only a connection to utilities—no additional cabling or interfaces needed.

Versatile Electronics: PEC provides both regenerative and linear electronics tailored to the system’s current and density requirements.

Degassing and Final Sealing

After Pre-Charge, the cells will be finally degassed, cleaned and sealed for further processing. An endcap will be laser welded over the filling hole, providing a clean and reliable closure of the cell.

The machine is also part of the Cell Finishing Line, using a micro-dry environment inside the machine. This way we avoid the complex logistics of moving pallets between the main dry room and formation area.

PEC’s proprietary laser welding technology provides minimum energy to the weld pool, reducing the area affected by heat.

Benefits:

- No complex logistics between Cell Formation Area and Dry Room

- Huge savings in energy due to micro-dry environment

- Better and more reliable seal

- Integrated cleaning process

Ageing (Room and High Temperature)

The equipment is positioned on both sides of an Automated Storage and Retrieval System (ASRS). The ASRS crane system will automatically transport the cells from one process step to the next until all process steps are finished and cells can be presented at the output conveyor.

The room temperature and high temperature ageing locations are also positioned next to the ASRS and are constructed out of high-bay storage racking. The racking is typically located inside temperature-controlled rooms, accessible for the ASRS crane through large sliding doors.